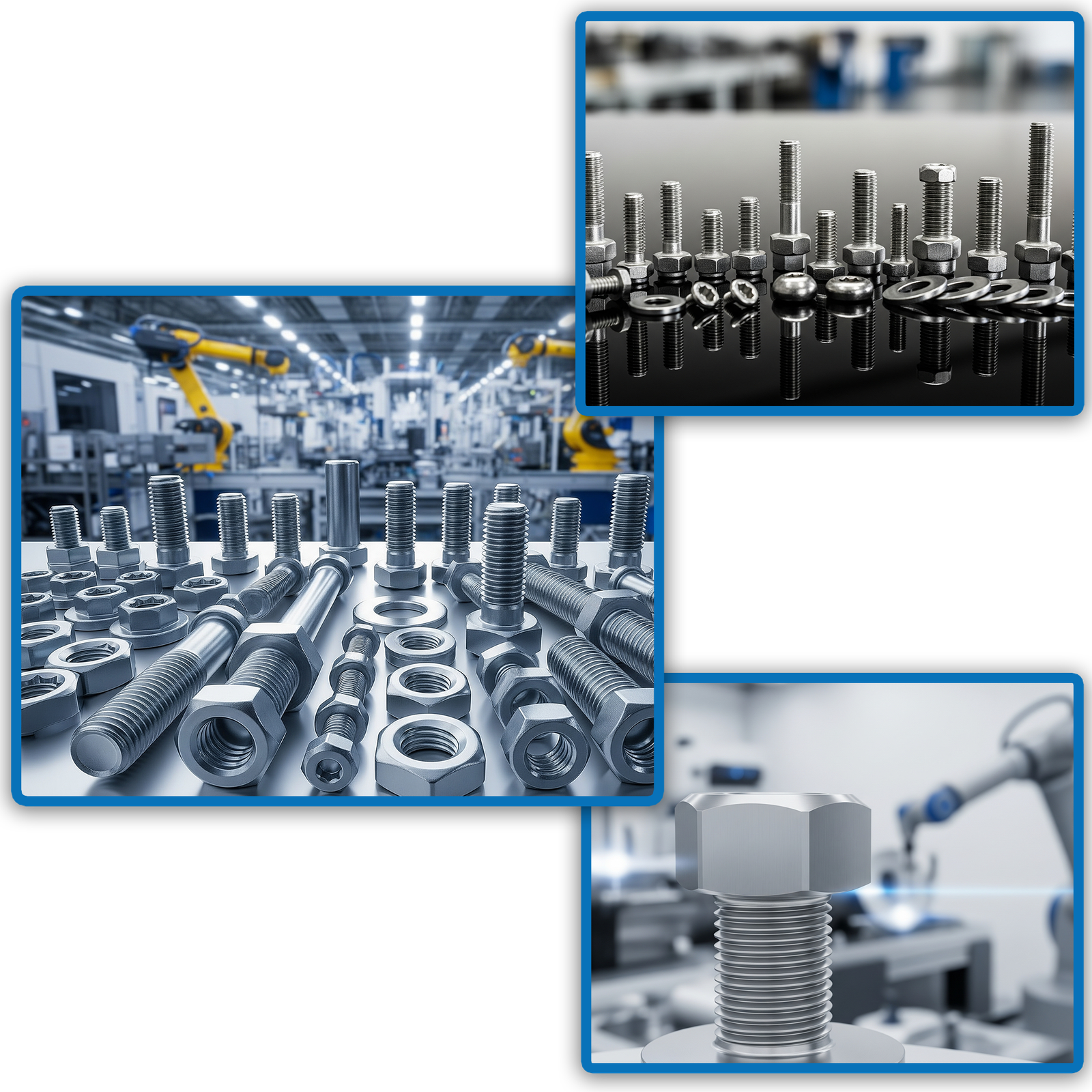

Manufacturing Capabilities

At FB Fasteners, we pride ourselves on utilizing advanced manu facturing technologies and processes to ensure precision, quality, and efficiency. Our commitment to innovation and continuous improvement allows us tomeet the exacting demands of global industries.

State-of-the-Art Machinery

with cutting-edge machinery that enables us to produce a wide range of fasteners with high accuracy and consistency, ensuring timely delivery and exceptional product performance. Our key machinery includes:

Wire Drawing Machines

In-house wire drawing capabilities to control material quality and size precision.

Multi-stationBoltFormers

High-speed automatic cold heading machines for precision bolt manufacturing, with capacities ranging from M6 to M16 in diameter and up to 160mm in length.

State-of-the-Art Machinery

with cutting-edge machinery that enables us to produce a wide range of fasteners with high accuracy and consistency, ensuring timely delivery and exceptional product performance. Our key machinery includes:

Wire Drawing Machines

In-house wire drawing capabilities to control material quality and size precision.

Multi-stationBoltFormers

High-speed automatic cold heading machines for precision bolt manufacturing, with capacities ranging from M6 to M16 in diameter and up to 160mm in length.

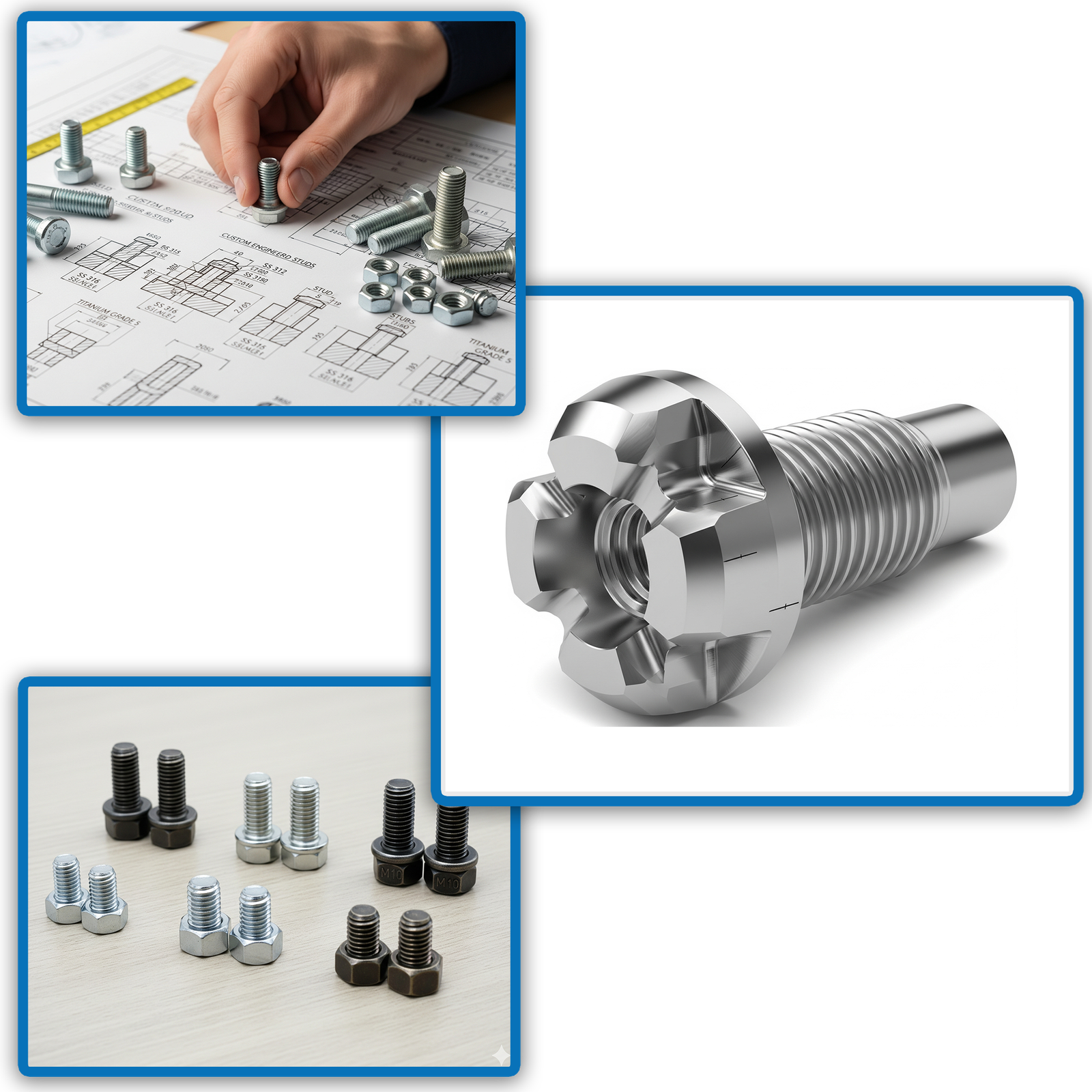

Precision Engineering & Customization

We offer customized fastener solutions tailored to meet the specific requirements of our clients. Our engineers work closely with customers to understand their unique needs and deliver products that meet the highest standards of performance.

Customization Options

We can accommodate specific designs, dimensions, and materials for bespoke fastener solutions.

Strict Tolerances

Our advanced equipment allows us to produce fasteners with strict dimensional tolerances to meet the most challenging application requirements.

Innovation & Technology

Equipped with PLC-controlled machines, we ensure precise, efficient, and consistent fastener production. Our commitment to continuous improvement keeps us at the forefront of innovation and quality in the industry.

PLC-Controlled Machines

For enhanced precision and efficiency in the production process, ensuring that every batch meets the same high standards.

Continuous Improvement

Our team is committed to innovation and regularly updates our processes and machinery to stay at the forefront of the fastener manufacturing industry.

Production Volume & Flexibility

With an annual capacity of 1,000 tons and a speed of up to 120 pieces per minute, we deliver fasteners in small or large batches with quick turnaround and uncompromised quality. Our expertise spans carbon steel, alloy steel, stainless steel, and more to meet diverse industry needs.

Annual Production Capacity

1,000 tons of fasteners across various sizes and materials.

Speed & Efficiency

With an average production speed of up to 120 pieces per minute, our operations are designed to handle both small and large batch orders, ensuring quick turnaround times without compromising on quality.

Materials Expertise

We work with a variety of materials, including carbon steel, alloy steel, stainless steel, and more, to cater to diverse industry needs.

Production Process

RAW MATERIAL SELECTION

The process starts with selecting premium-quality raw materials, usually steel wire rods. These rods are carefully chosen based on the precise specifications and performance requirements of the fasteners, ensuring durability, strength, and reliability in every application.

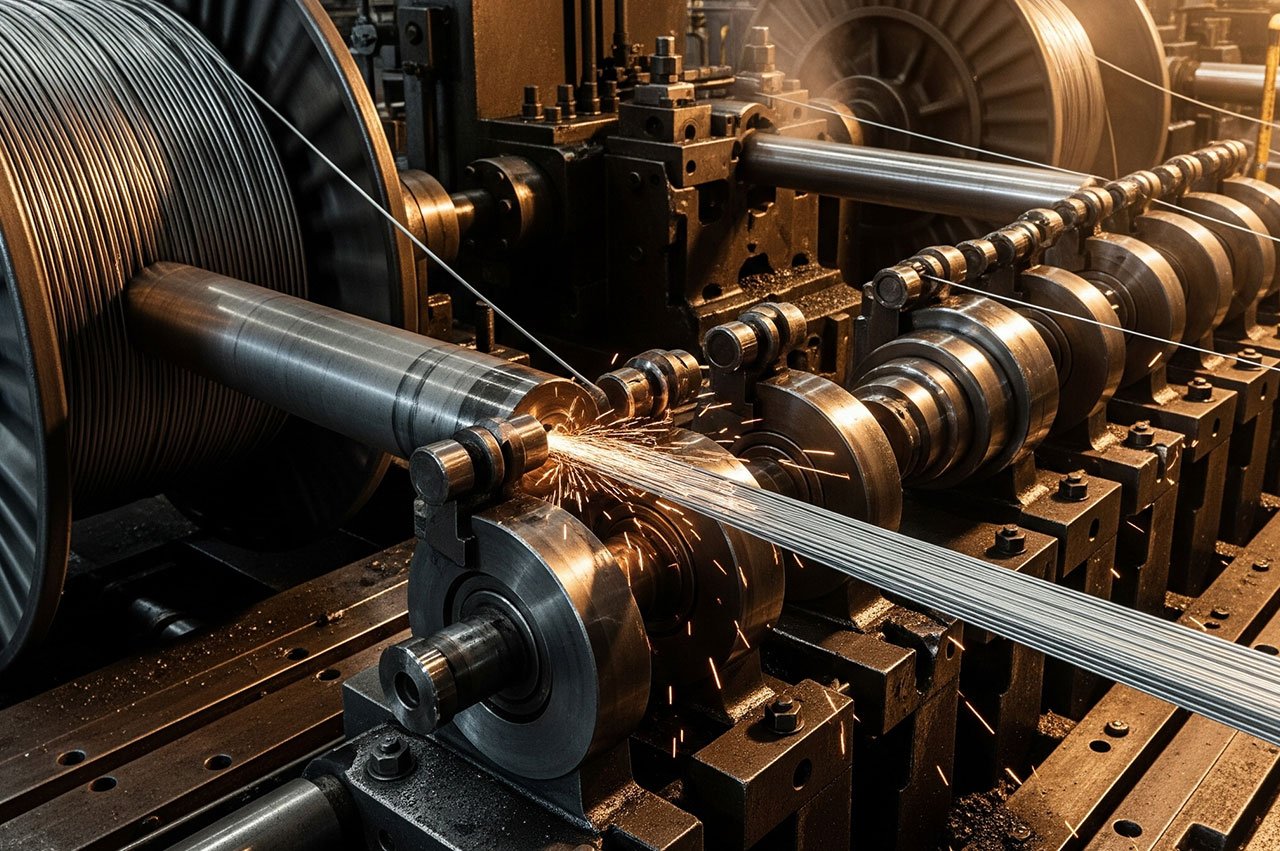

WIRE DRAWING

The selected steel wire rods are carefully drawn through a series of precision-engineered dies, gradually reducing their diameter to the exact required size. This process ensures uniformity, accuracy, and optimal quality for producing durable and high-performance fasteners

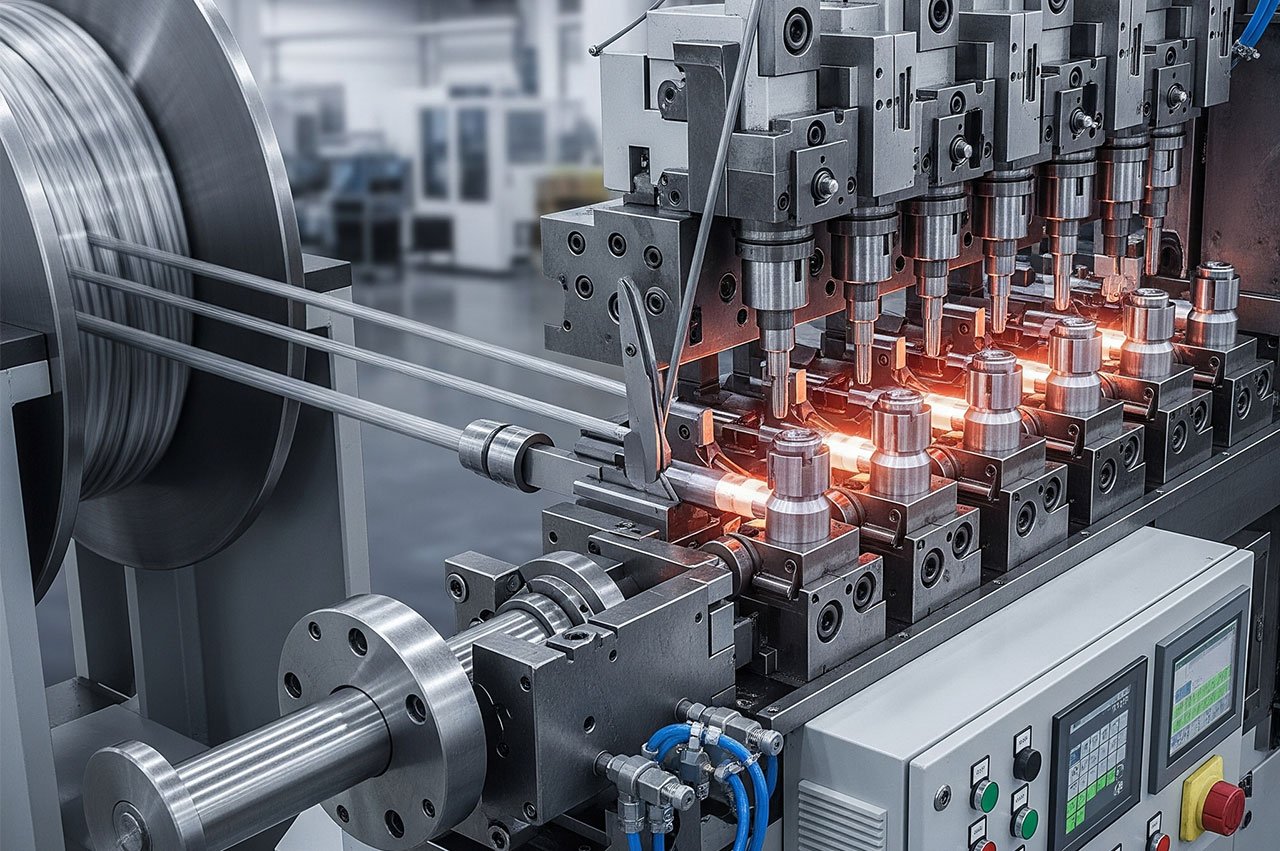

COLD HEADING

In the cold heading process, steel wire is accurately cut into specific lengths and shaped into the desired form using advanced, high-speed, multi-station cold heading machines, ensuring precision, consistency, and efficiency in producing high-quality fasteners.

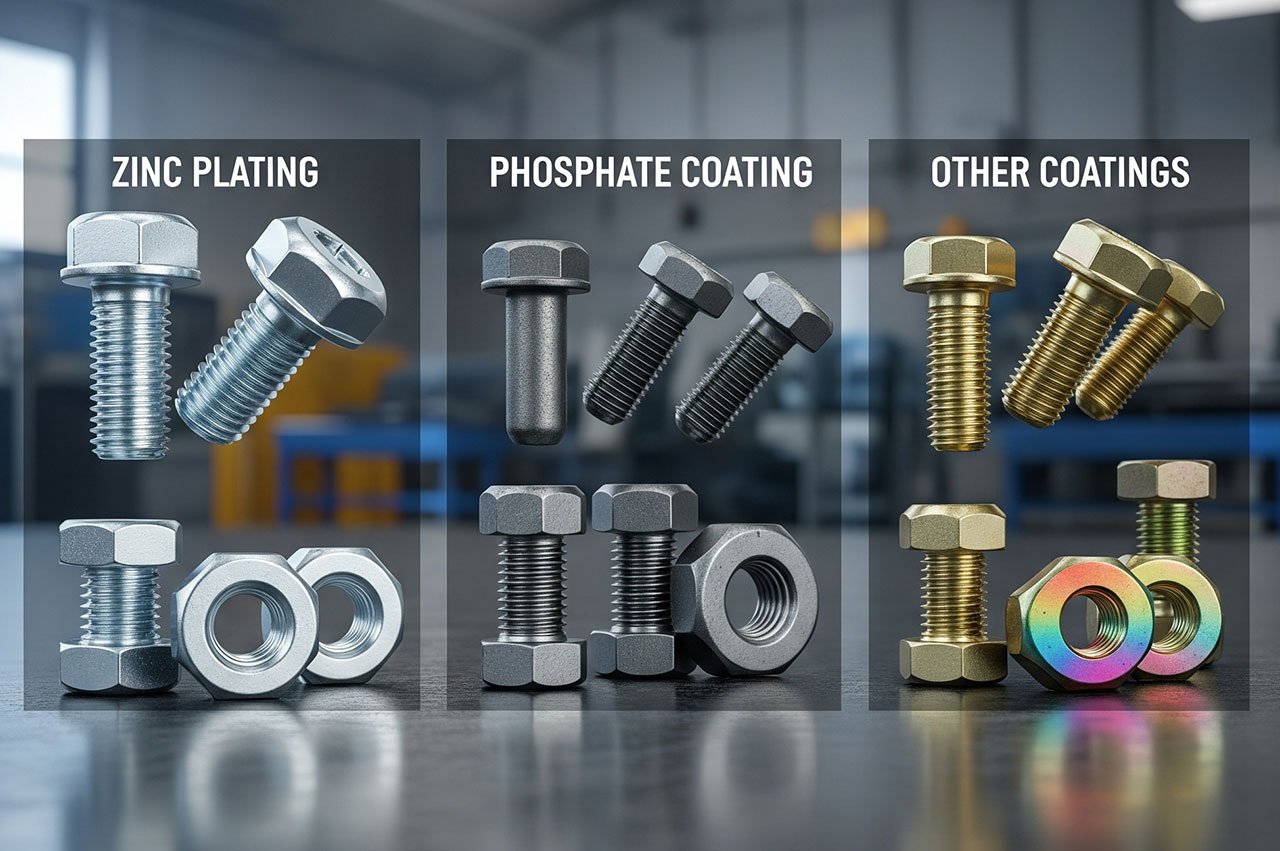

SURFACE TREATMENT

Surface treatment is applied to enhance fasteners’ corrosion resistance and appearance. Common processes include zinc plating, phosphate coating, and other advanced protective coatings, ensuring durability, performance, and a professional finish for various industrial applications

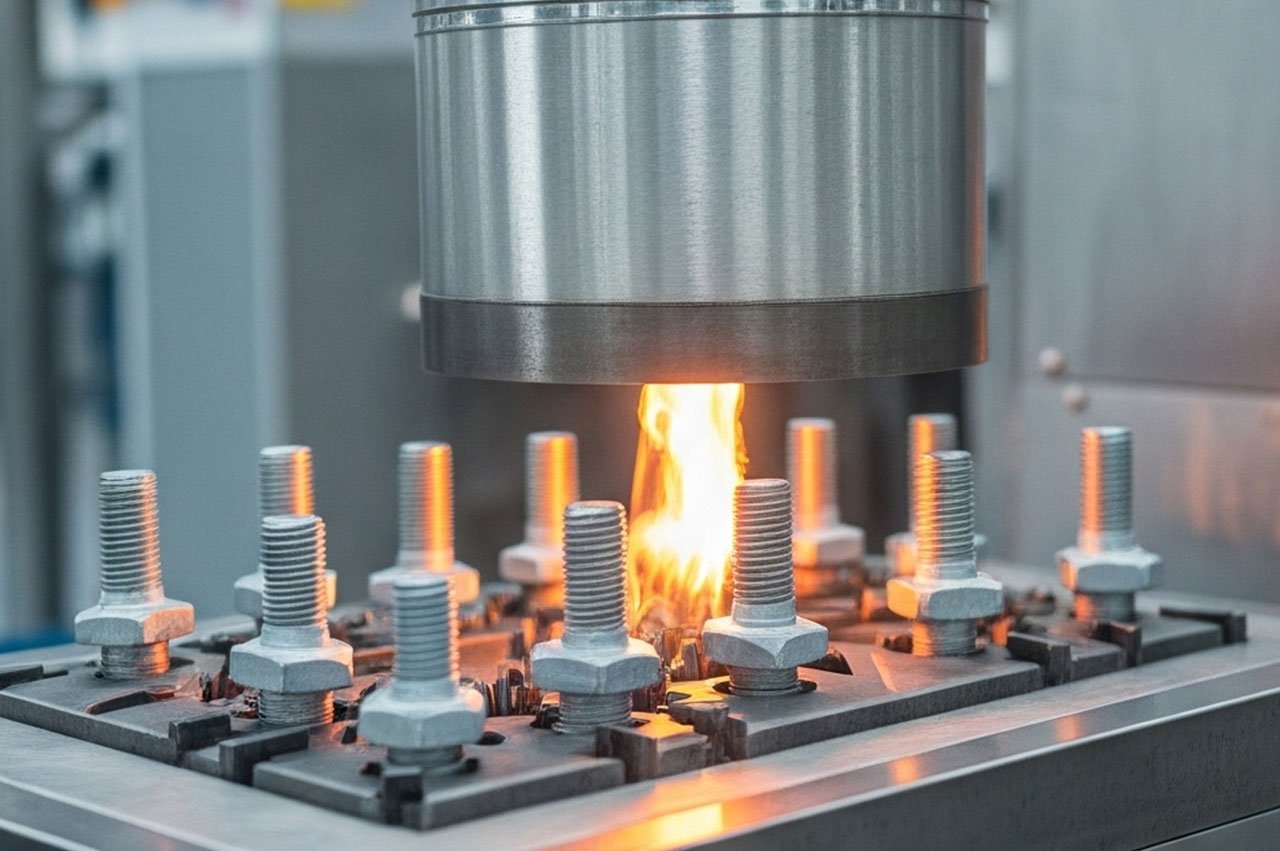

HEAT TREATMENT

Formed fasteners undergo advanced heat treatment to improve strength and performance. The process includes precise hardening in controlled furnaces with rapid quenching, followed by tempering in electric furnaces to reduce brittleness, enhance toughness, and ensure durability.

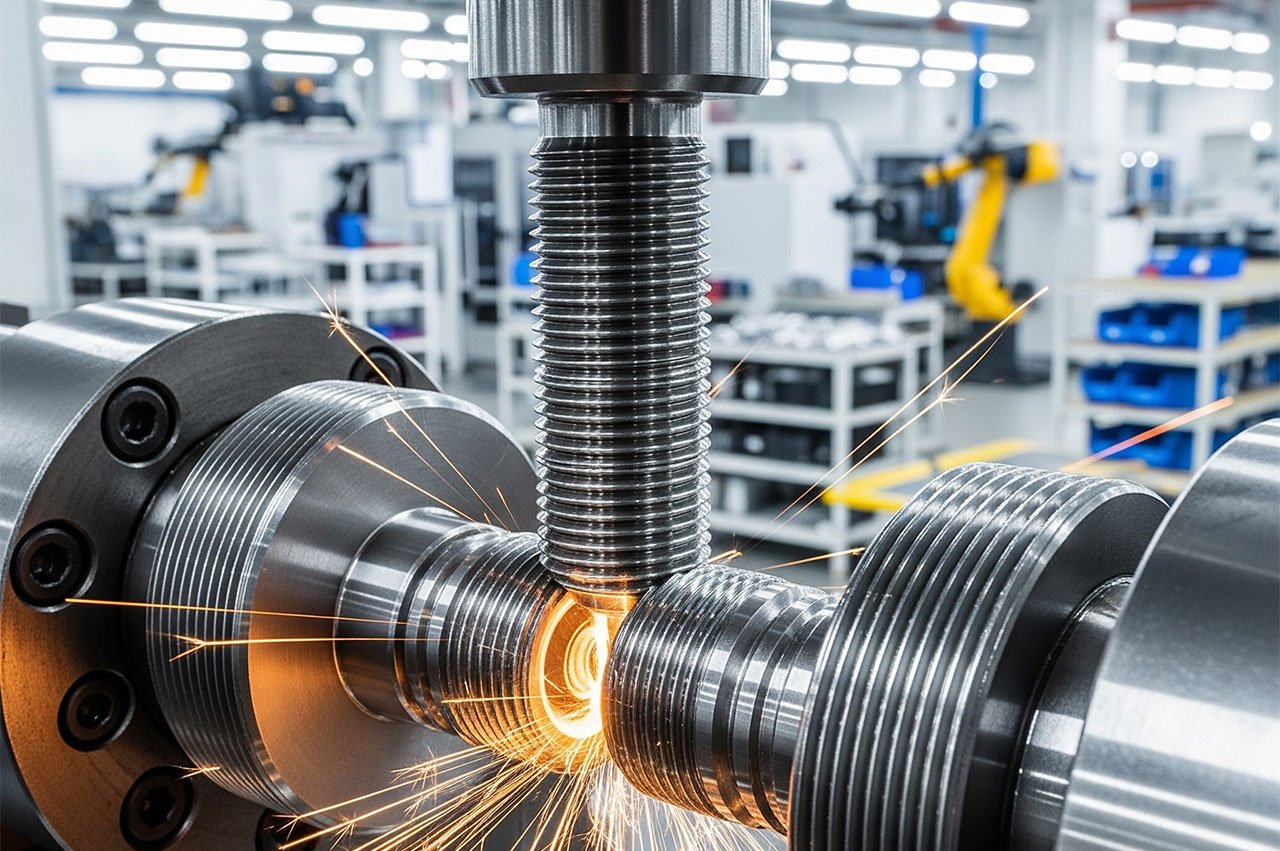

THREAD ROLLING

Thread rolling is a vital step where threads are precisely formed on the shank of fasteners. Using advanced German and Japanese machines, blank fasteners are rolled between two hardened dies, ensuring accurate thread geometry, strength, durability, and consistent quality.

QUALITY CONTROL

Quality is paramount at FB Fasteners. Rigorous testing and inspection are carried out at each stage of production to ensure compliance with industry standards and customer specifications. This includes: Dimensional Checks Tensile Testing Visual Inspection

PACKAGING

Once the fasteners successfully pass all strict quality control checks, they are thoroughly cleaned to remove any residues, carefully dried to prevent corrosion, and then securely packaged with precision to ensure safe handling, storage, and delivery to customers.

SHIPPING

The final step is shipping the finished products to customers. We ensure reliable, timely, and secure delivery by leveraging our strong, well-integrated logistics network, enabling us to reach clients quickly, efficiently, and with complete satisfaction guaranteed.